Email cannot be empty

Password cannot be empty

Email format error

Email cannot be empty

Email already exists

6-20 characters(letters plus numbers only)

The password is inconsistent

Email format error

Email cannot be empty

Email does not exist

6-20 characters(letters plus numbers only)

The password is inconsistent

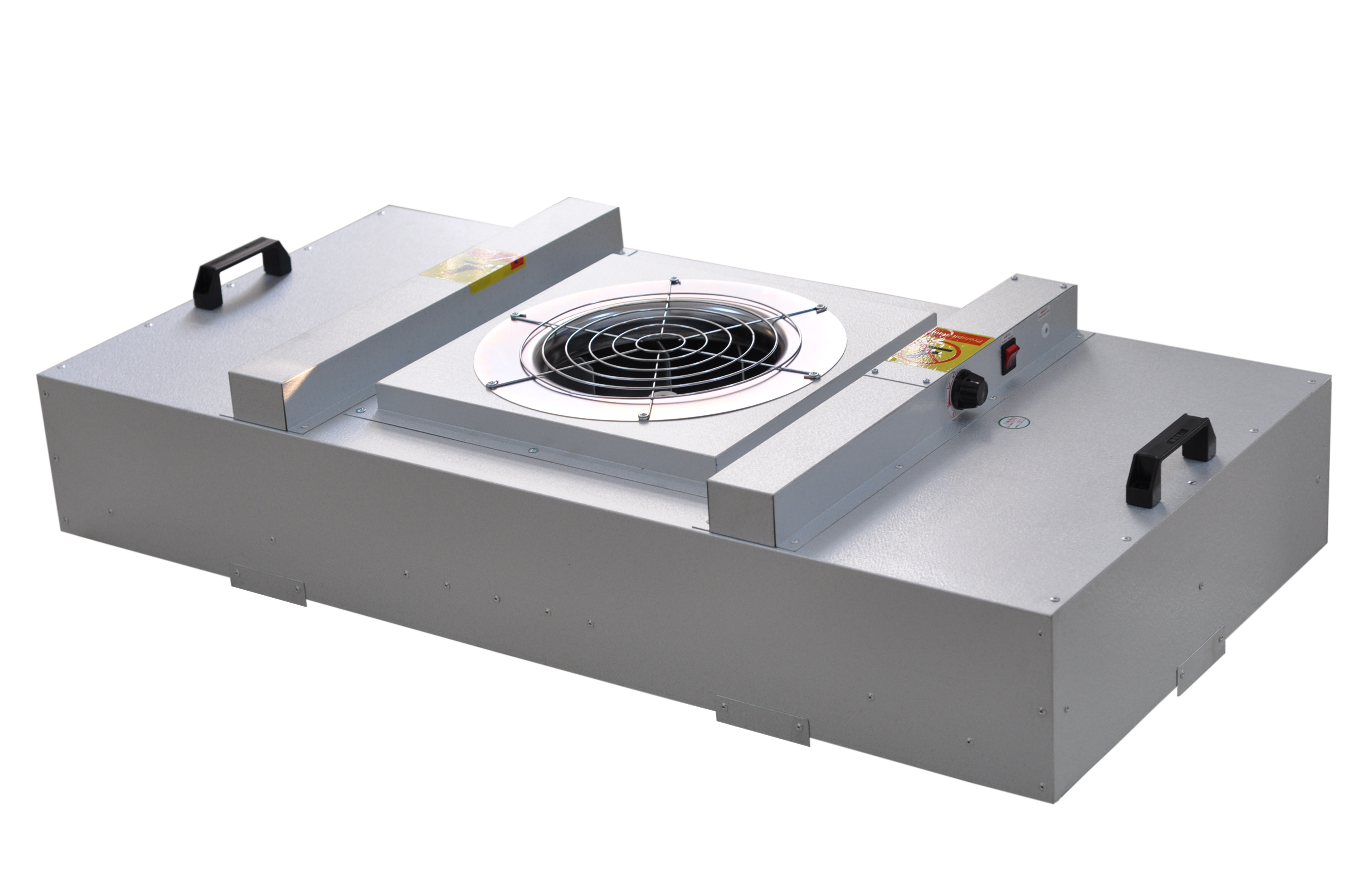

Air Shower Pass-Through Box

Meet the DSX Advanced Air Shower Pass-Through Box, a top-tier solution for enhancing cleanliness and sterility in controlled environments. Constructed from durable stainless steel, this system employs high-velocity air jets filtered through HEPA/ULPA filters to scrub contaminants from surfaces.

Its modular design allows for easy customization, while adjustable airspeed and airflow direction optimize the decontamination process. Additional features like UV sterilization and air ionization can be included for enhanced performance.

The DSX Air Shower Pass-Through Box features secure access control, transparent viewing windows for monitoring, and energy-efficient operation. Suitable for industries like pharmaceuticals, biotechnology, semiconductor manufacturing, and more, this system ensures cleanliness and sterility in critical environments.

Product Introduction: DSX Air Shower Pass-Through Box

Elevate the cleanliness and sterility of your controlled environment with the advanced DSX Air Shower Pass-Through Box. This state-of-the-art system combines a built-in air shower with high-velocity ULPA-filtered air jets to effectively reduce surface contamination on materials and personnel entering or exiting sensitive areas.

The DSX Air Shower Pass-Through Box is engineered with high-velocity air jets ranging from 18 to 30 meters per second, directed through an array of stainless steel nozzles. These powerful air jets meticulously "scrub" contaminants from surfaces, ensuring optimal cleanliness. Contaminated air is then drawn through the base of the unit, filtered, and recirculated, maintaining a pristine and controlled environment.

Safety and security are paramount with the DSX Air Shower Pass-Through Box. The system features an electrical interlocking door mechanism that ensures secure access control, preventing cross-contamination. The base surface is constructed from perforated stainless steel 304, making it easy to clean and maintain, thereby ensuring optimal hygiene standards.

Seamless monitoring of the internal chamber is facilitated by transparent viewing windows, providing a clear view of ongoing processes. The pass-through box is equipped with a DSX high-quality centrifugal motor renowned for its efficiency, energy-saving capabilities, quiet operation, and reliable performance. The integrated blower assembly is designed for optimal motor cooling, ensuring smooth, quiet, and vibration-free operation.

Key Features of the DSX Air Shower Pass-Through Box:

- High-Efficiency Air Shower System: Removes contaminants from incoming materials and personnel, ensuring cleanliness.

- Automated Interlocking Doors: Prevent cross-contamination by ensuring secure access control.

- HEPA/ULPA Filters: Efficiently remove particles and microorganisms, maintaining cleanroom integrity.

- Stainless Steel Construction: Provides durability and compatibility with cleanroom environments.

- Programmable Control Panel: Allows for customized operation based on specific requirements.

- Pass-Through Capabilities: Enables seamless transfer of items into and out of controlled environments.

- Pressure Differential Technology: Maintains cleanroom integrity by managing air pressure differences.

- Easy Maintenance and Cleaning: Designed for straightforward cleaning procedures to ensure hygiene.

- Optional Additional Features: UV sterilization and air ionization for enhanced decontamination.

- High-Velocity Airflow: Thoroughly removes contaminants and debris.

- Energy-Efficient Operation: Minimizes environmental impact and reduces operating costs.

- Transparent Viewing Windows: Facilitates monitoring of items inside the pass-through box.

- Emergency Stop Button: Immediate shutdown in case of issues for operator safety.

- User-Friendly Interface: Easy control and monitoring of air shower pass-through box operations.

- Adjustable Airspeed and Airflow Direction: Optimizes the decontamination process.

- Alarm Systems: Alerts for filter replacement or maintenance requirements.

- Modular Design: Easy installation and customization based on specific needs.

- Smooth Surfaces and Rounded Corners: Easy cleaning and sanitation.

- Trusted Brand Reputation: Proven reliability in the cleanroom equipment industry.

Applications of the DSX Air Shower Pass-Through Box:

- Pharmaceutical Industry: Transfers materials and equipment into cleanrooms to prevent contamination and maintain product integrity.

- Biotechnology Facilities: Ideal for passing through biological samples, laboratory equipment, and sensitive materials.

- Semiconductor Manufacturing: Maintains cleanliness during the transfer of sensitive electronic components and devices.

- Medical Device Manufacturing: Ensures a sterile environment when transferring medical devices, instruments, and supplies.

- Research Laboratories: Prevents the introduction of contaminants when moving samples, research materials, and equipment.

- Food and Beverage Processing: Maintains cleanliness when transferring raw materials, packaging, or finished products.

- Aerospace Industry: Decontaminates tools, parts, and components before entering critical production areas.

- Hospitals and Healthcare Facilities: Minimizes the spread of pathogens when transferring supplies, medications, and medical equipment.

- Optics and Electronics Industry: Maintains cleanliness and prevents damage to sensitive components.

- Cleanroom Environments: Suitable for various industries requiring controlled and sterile environments.

Experience the cutting-edge features and superior performance of the DSX Air Shower Pass-Through Box, designed to meet the highest standards of cleanliness and safety. This innovative system is the ultimate solution for maintaining a pristine and controlled environment in your facility.

All products can be customized as actual requirement

Product Showcase · Excellent Quality

|

|

|

| Laser cutting | CNC bending Center | CNC Punch Press Punching |

|

|

|

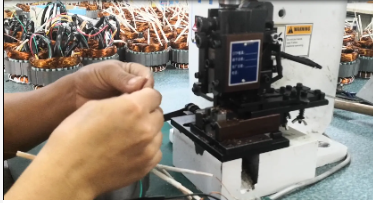

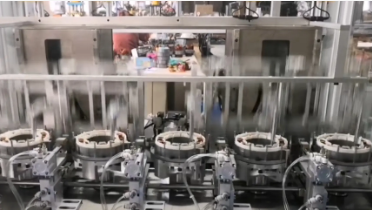

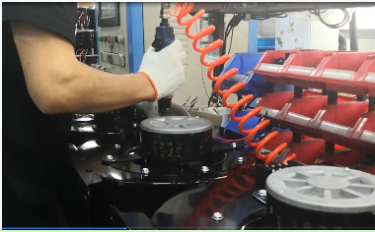

| CNC bending | DSX Motor production | Motor production |

|

|

|

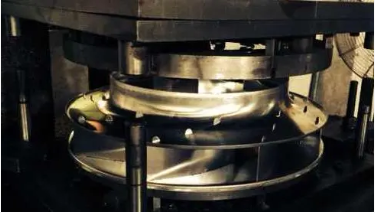

| Motor production | Produce impeller | Balancing the impeller |

|

|

|

| Motor test | Blower production | Blower testing |

|

|

|

| Chemical filters Production | Chemical filters Production | Chemical filters Production |

|

|

|

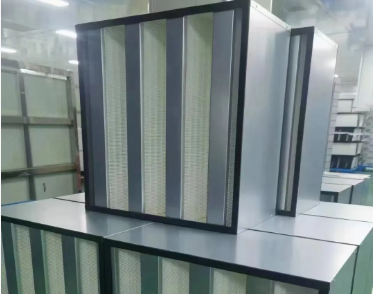

| HEPA filter workshop | Special filter Production | W-type filter production |

|

|

|

| High temperature filter | Rivet workshop | Laser welding |

|

|

|

| Welding workshop | Welding workshop | Cutting of profiles |

|

|

|

| FFU assembly | FFU assembly | FFU assembly |

|

|

|

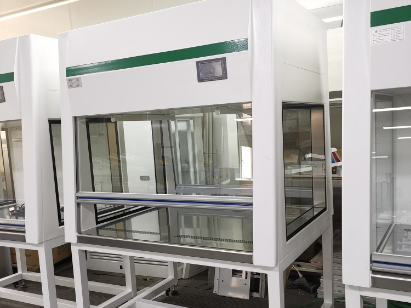

| Air shower room assembly | Clean bench production workshop | Clean bench production workshop |

|

|

|

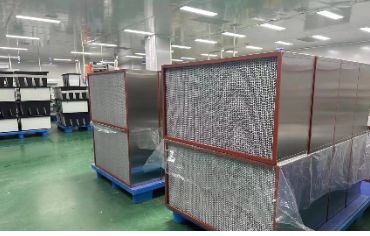

| Pass boxes production workshop | HEPA BOXES production workshop | HEPA Boxes test |

|

|

|

| EFU production | Warehouse | Shipment |

FAQs for DSX Air Shower Pass-Through Box

Q1: What is the main function of the DSX Air Shower Pass-Through Box?

A: The DSX Air Shower Pass-Through Box is designed to elevate the cleanliness and sterility of controlled environments by effectively reducing surface contamination on materials and personnel entering or exiting sensitive areas. It utilizes high-velocity ULPA-filtered air jets to scrub contaminants from surfaces.

Q2: What materials are used in the construction of the DSX Air Shower Pass-Through Box?

A: The DSX Air Shower Pass-Through Box is constructed with stainless steel for durability and compatibility with cleanroom environments. The base surface is made of perforated stainless steel 304, which is easy to clean and maintain.

Q3: How does the air shower system work?

A: The air shower system operates by directing high-velocity air jets, ranging from 18 to 30 meters per second, through an array of stainless steel nozzles. These air jets meticulously scrub contaminants from surfaces, and the contaminated air is then drawn through the base of the unit, filtered, and recirculated.

Q4: What safety features are included in the DSX Air Shower Pass-Through Box?

A: The system features an electrical interlocking door mechanism for secure access control, preventing cross-contamination. It also includes an emergency stop button for immediate shutdown in case of issues, ensuring operator safety.

Q5: Can the DSX Air Shower Pass-Through Box be customized?

A: Yes, the DSX Air Shower Pass-Through Box features a modular design that allows for easy installation and customization based on specific needs. Additionally, it has adjustable airspeed and airflow direction to optimize the decontamination process.

Q6: What types of filters are used in the DSX Air Shower Pass-Through Box?

A: The DSX Air Shower Pass-Through Box utilizes HEPA/ULPA filters to efficiently remove particles and microorganisms, maintaining cleanroom integrity.

Q7: How is the cleanliness of the internal chamber monitored?

A: The pass-through box is equipped with transparent viewing windows that facilitate monitoring of the internal chamber, providing a clear view of ongoing processes.

Q8: What are some of the optional additional features available for the DSX Air Shower Pass-Through Box?

A: Optional additional features include UV sterilization and air ionization for enhanced decontamination. These features can be added based on specific requirements and applications.

Q9: What are the main applications of the DSX Air Shower Pass-Through Box?

A: The DSX Air Shower Pass-Through Box is suitable for various industries requiring controlled and sterile environments, including pharmaceutical, biotechnology, semiconductor manufacturing, medical device manufacturing, research laboratories, food and beverage processing, aerospace, hospitals and healthcare facilities, optics and electronics, and cleanroom environments.

Q10: How energy-efficient is the DSX Air Shower Pass-Through Box?

A: The DSX Air Shower Pass-Through Box is designed for energy-efficient operation, minimizing environmental impact and reducing operating costs. It features a high-quality centrifugal motor renowned for its efficiency and energy-saving capabilities.

Q11: How often do the filters need to be replaced?

A: The frequency of filter replacement depends on the usage and contamination levels in the specific environment. The DSX Air Shower Pass-Through Box is equipped with alarm systems that alert for filter replacement or maintenance requirements, ensuring optimal performance and cleanliness.

Q12: Is the DSX Air Shower Pass-Through Box easy to maintain and clean?

A: Yes, the DSX Air Shower Pass-Through Box is designed for straightforward cleaning procedures to ensure hygiene. Its smooth surfaces and rounded corners make it easy to clean and sanitize.

By addressing these common questions, we hope to provide a better understanding of the DSX Air Shower Pass-Through Box and its features, benefits, and applications.